TC Wafer Wireless - On Wafer System

TC Wafer Wireless(On-Wafer) For Dry Etch and Wet Clean Process

- Wafer size: 8″, 12″

- Temperature precision: ±0.1℃-0.2℃

- Temperature measure range: 15-100℃

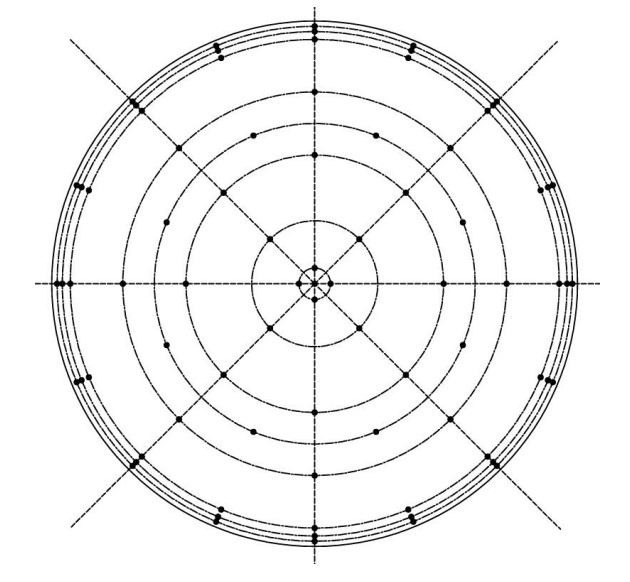

- Number of measurement point: 1~81

Send Us In Inquiry:

Product Introduction

TC Wafer Wireless – Actual Monitoring Wafer Temperature On Dry Etch / Wet Clean Process

The TC Wafer Wireless (On Wafer system) Temperature Measurement System is a complete measurement system embedded in a wafer that can measure and record the impact of the dry etch process environment on production wafers under actual process conditions, without the need for wired connections. The on wafer system can actually monitoring wafer temperature on dry etch process, designed to calibrate, improve uniformity and match temperature profiles.

By measuring temperature data at conditions close to the product process, the On-Wafer wireless temperature measurement system can help process engineers adjust etch process conditions, verify and match chambers, and validate after PM.

Specifications

| Item No. | Item | Data |

| 1 | Wafer size | 8”,12” |

| 2 | Wafer material | Silicon |

| 3 | Surface material | Silicon |

| 4 | Number of measurement point | 81/65 |

| 5 | Sensor type | IC |

| 6 | Temperature test range | Dry Etch: 15-100℃ |

| Wet Clean: 15-120℃ | ||

| 7 | Manufacturing tool temperature test range | Dry Etch: 12-85℃ |

| Wet Clean: 15-120℃ | ||

| 8 | Precision | 0.1℃/0.2℃ |

| 9 | Thickness | 1.2mm |

| 10 | Connection | RF |

| 11 | Power | battery |

| 12 | Charge | bluetooth |

| 13 | Sampling frequency | 1Hz/2Hz/4Hz |

| 14 | Application | Wet clean, Dry Etch |

Software demostration Interface

Applications

Wet clean

Dry Etch

Customization

1. Determine the temperature accuracy requirements and dimensions.

2. Determine the usage environment and whether it meets the requirements (currently, 8-inch wireless temperature measurement wafers can be used in plasma and ESC environments).

3. Determine the number and arrangement of points.