RTD Wafer

RTD Wafer, High Temperature Precision Testing System

- Wafer size: 4″, 6″, 8″, 12″

- Temperature precision: ±0.01℃

- Temperature measure range: -40-250℃

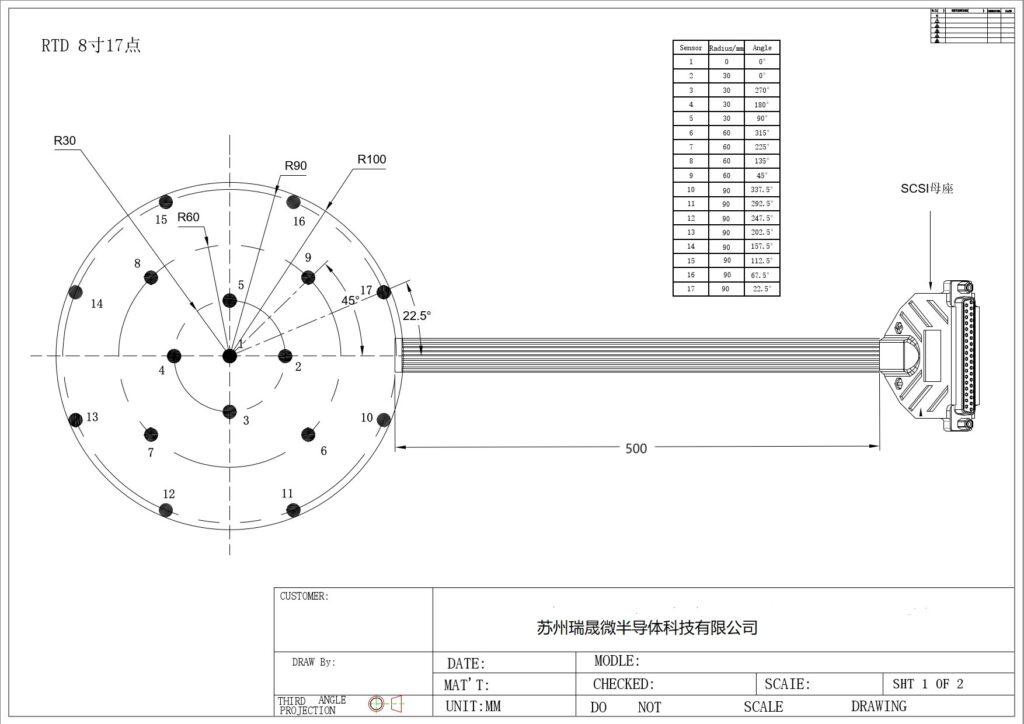

- Number of measurement point: 1~97

Send Us In Inquiry:

RTD Wafer

Product Introduction

RTD Wafer(Or called the Instrumented Wafer or Bonded Wafer) is a temperature sensor that uses a special processing technology to embed temperature sensors (resistance temperature detector) at specific locations on the wafer surface, thus realizing real-time temperature measurement of the wafer surface.

Through RTD Wafer, the real-time temperature measurement values of specific points on the wafer and the temperature distribution of the overall wafer can be obtained; it can also be used to continuously monitor the transient temperature changes of the wafer during the heat treatment process.

The instrumented wafers are being used in many industries including Rapid Thermal Processing (RTP), Rapid Thermal Annealing (RTA), coating /developing.

Specifications

| Item No. | Item | Data |

| 1 | Precision | ±0.05℃(-80-250℃,0-250℃) |

| ±0.5℃(-80-350℃,0-350℃) | ||

| 2 | Measurement range | -80~250℃(±0.05℃) |

| -80-350℃(±0.5℃) | ||

| 3 | Temp resolution | 0.01℃ |

| 4 | TC type | PT |

| 5 | Number of measurement point | 1~81 |

| 6 | Wafer material | Silicon/sapphire, etc. |

| 7 | Wafer size | 2”,4”,6”,8”,12” |

| 8 | Connection | Wire/Wireless |

| 9 | Thickness | 2~3.5mm |

| 10 | Application | Track、ALD、Prob station、High-precision hot plate |

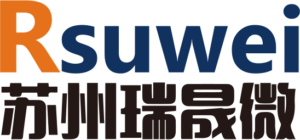

Software demostration Interface

Applications

Track

ALD

Prob station

High-precision hot plate

Customization

1. Determine the temperature accuracy requirements and dimensions.

2. Determine the vacuum requirements.

3. Determine the number and arrangement of points.

4.Determine the length of the lead wire.