TC Wafer

TC Wafer With Wire

- Wafer size: 4″, 6″, 8″, 12″

- Temperature precision: ±1.1℃/0.4%

- Temperature measure range: RT~1200℃

- Number of measurement point: 1~34

Send Us In Inquiry:

TC Wafer

Product Introduction

TC Wafer is a temperature sensor that uses a special processing technology to embed high-temperature resistant sensors (thermocouples) at specific locations on the wafer surface, thus realizing real-time temperature measurement of the wafer surface.

TC Wafer can obtain real-time temperature measurement values of specific locations on the wafer and the temperature distribution of the overall wafer; It can also be used to continuously monitor the transient temperature changes of the wafer during the heat treatment process, such as: heating up, cooling down, constant temperature process, and delay time.

Specifications

| Item No. | Item | Data |

| 1 | Precision | K:±1.1℃/0.4%; |

| R/S:±0.6℃/0.1%; | ||

| T:±0.5℃; | ||

| 2 | Measurement range | K:RT~1200℃; |

| R/S:RT~1200℃; | ||

| T:RT~350℃; | ||

| 3 | Sensor type | TC |

| 4 | TC type | K/R/S/T |

| 5 | TC wire diameter | 0.127mm(For vacuum), 0.254mm(non-vacuum) |

| 6 | Number of measurement point | 1~34 |

| 7 | Base material | Silicon/sapphire, etc. |

| 8 | Wafer size | 2”,4”,6”,8”,12” |

| 9 | Wire length | L1-Inside the chamber;L2-Chamber transition section;L3-Outside the chamber |

| 10 | Application | PVD、ALD、CVD、RTP/RTA、Stripper, Bonding(BEOL), Track, Hot plate. |

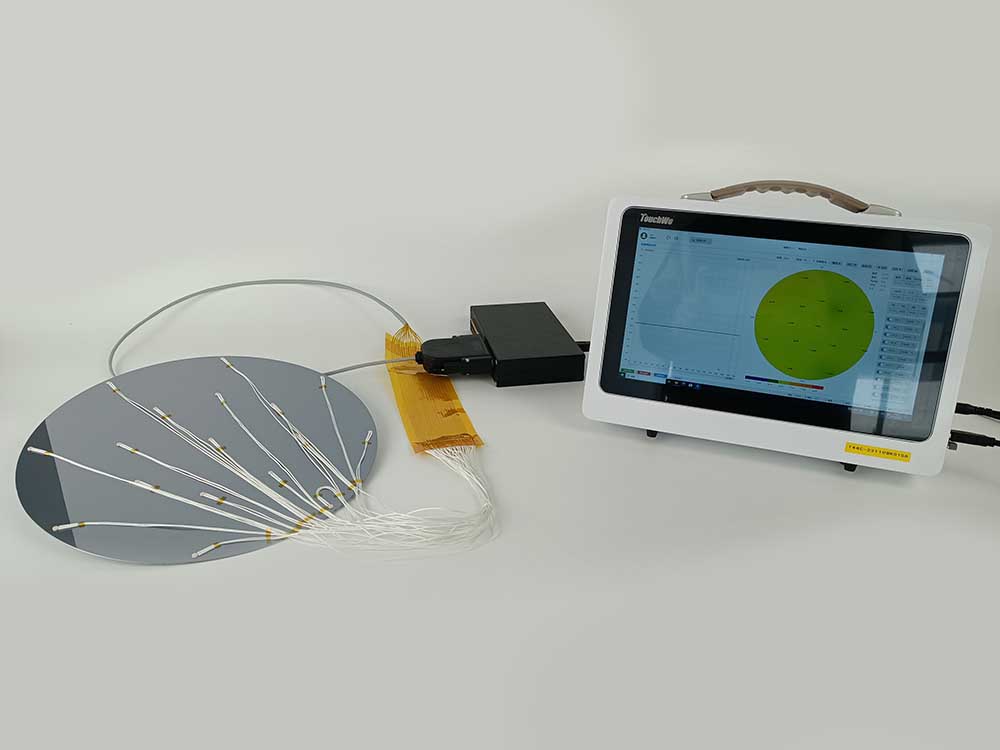

Software demostration Interface

Applications of TC Wafer

PVD

ALD

CVD

RTP/RTA

Stripper

Bonding(BEOL)

Track

Hot plate

Customization

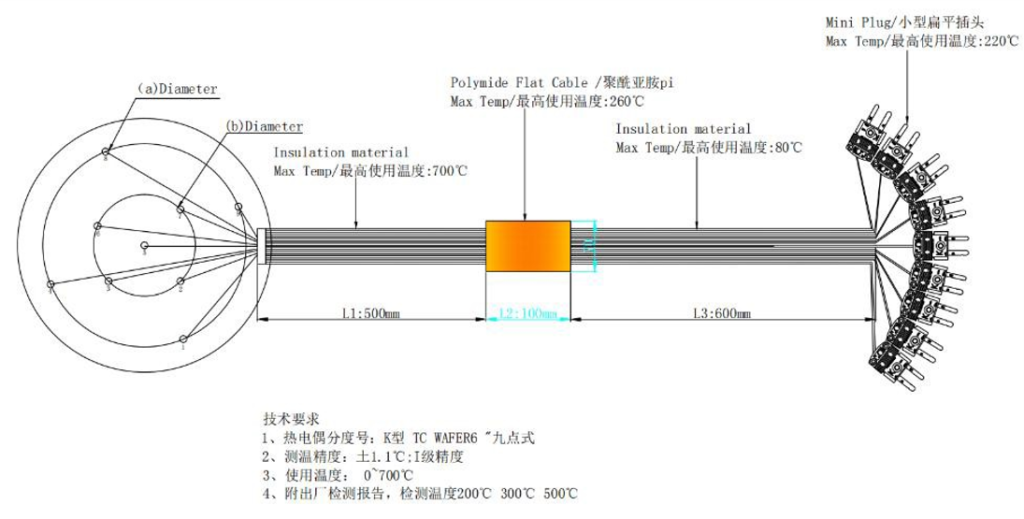

TC Wafer can be customized to fit your equipment. To do custom thermocouple wafer, please provide us the information as specified below:

1. Determine the temperature range, accuracy requirements, and dimensions (TC type corresponding to different temperatures and accuracies)

2. Determine the vacuum requirements (mainly consider the width and thickness of the transition section L2 at the chamber door)

3. Determine the number and distribution of measurement points (flexible customization)

4. Determine the length of each segment L1, L2, L3 (mainly consider the length of the TCWafer placed in the chamber)

Others: connector type

TC Wafer Drawings